The Essentials of Cost-Effective Plastic Packaging Bag Printing

Understanding the intricacies of plastic packaging bag printing is essential for businesses looking to optimize costs while maintaining quality. The process involves printing designs, logos, or information on plastic bags, which are widely used in various industries. Cost-efficiency in packaging is crucial as it directly impacts a company’s bottom line and customer satisfaction.

Several key factors influence the cost of printing plastic packaging bags, including the type of materials used, the complexity of the design, the printing technique employed, and the quantity ordered.

Bulk Discounts: Maximizing Savings

One of the most effective ways to reduce printing costs is through bulk orders. Bulk discounts are price reductions offered to customers who purchase large quantities. These discounts are calculated based on the volume of the order, with larger orders typically receiving higher discounts.

To negotiate better rates with suppliers, it's essential to understand their pricing structure and be transparent about your budget and needs. Successful businesses often leverage bulk discounts to significantly reduce their packaging costs, enabling them to offer competitive pricing to their customers.

Case studies reveal that companies like XYZ Corp and ABC Ltd. have saved up to 30% on their packaging costs by ordering in bulk.

Manufacturer Direct Options: Cutting Out the Middleman

Purchasing directly from manufacturers can further enhance cost savings. Manufacturer direct purchasing eliminates the need for intermediaries, thereby reducing additional costs. Advantages include lower prices, better quality control, and direct communication with the source.

To find reliable manufacturers, conduct thorough research, check reviews, and request samples. Comparing manufacturer direct options with third-party suppliers often reveals significant cost differences.

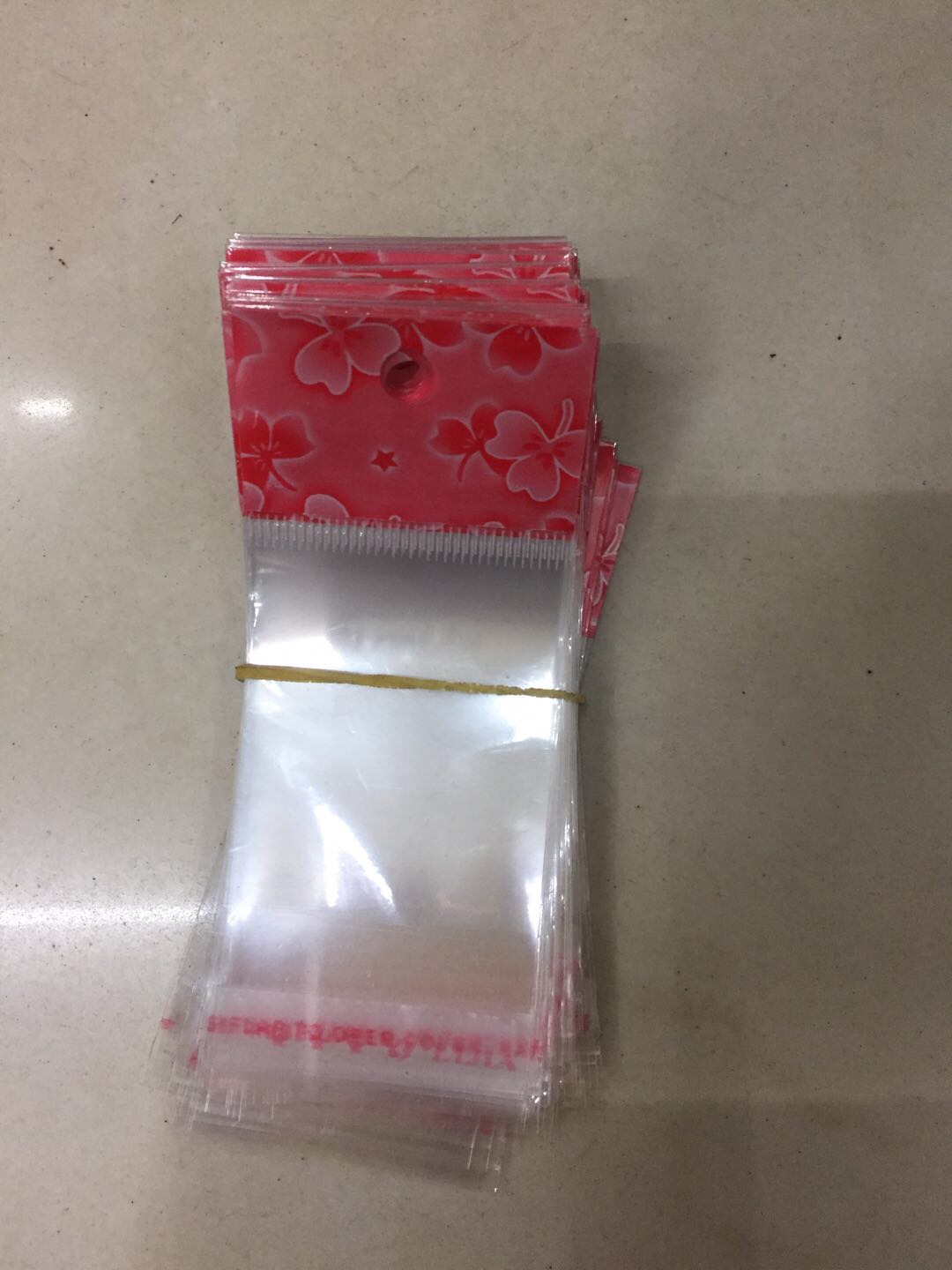

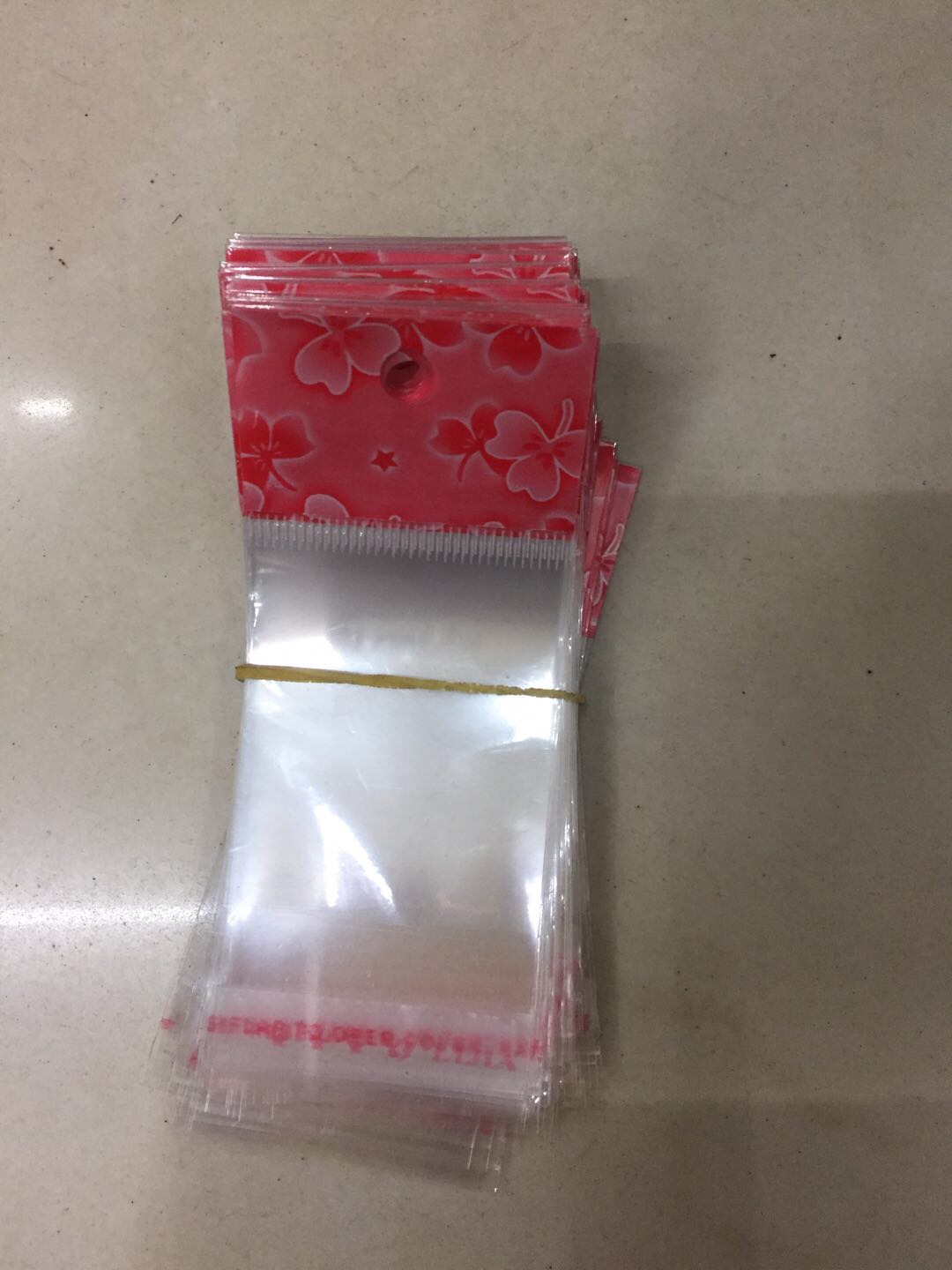

Custom Sample Orders: Tailoring to Your Needs

Custom samples play an essential role in ensuring that the final product meets your specifications. The process involves ordering a small batch of customized packaging bags to evaluate their quality and make necessary adjustments before placing a large order.

While custom samples can incur additional costs, they are a worthwhile investment to avoid costly mistakes in bulk orders. Carefully evaluate the sample quality, and communicate any adjustments to the manufacturer.

Balancing Quality and Cost

Maintaining high quality on a budget requires strategic planning. One effective strategy is to select materials that offer both durability and cost-effectiveness. Common pitfalls, such as compromising on quality for lower costs, can lead to customer dissatisfaction and increased returns.

By focusing on long-term savings and building strong supplier relationships, businesses can achieve the right balance between quality and cost.

Eco-Friendly Alternatives

With increasing environmental awareness, many companies are exploring eco-friendly plastic packaging options. While these alternatives may initially seem more expensive, they offer long-term benefits such as enhanced brand image and customer loyalty.

Comparing costs between traditional and eco-friendly materials can help businesses make informed decisions that align with their sustainability goals.

Tips for Efficient Order Management

Efficient order management is crucial for maintaining a steady supply of packaging materials. Best practices include tracking inventory levels, forecasting future needs, and coordinating with suppliers to ensure timely deliveries. Utilizing tools and software for inventory management can streamline the process and prevent stockouts or overstocking.

Future Trends in Plastic Packaging Bag Printing

The plastic packaging industry is continually evolving with emerging technologies and innovations. Advances in printing techniques and sustainable materials are set to shape the future of packaging. Keeping abreast of these trends can help businesses stay competitive and adapt to changing market demands.

Resources and Further Reading

For more information on plastic packaging bag printing, consider exploring the following resources:

Frequently Asked Questions (FAQs)

Q: How are bulk discounts calculated?

A: Bulk discounts are typically calculated based on the volume of the order. Larger orders receive higher discounts as they lower the per-unit cost for suppliers.

Q: What are the benefits of manufacturer direct purchasing?

A: Buying directly from manufacturers eliminates intermediaries, resulting in lower costs, better quality control, and direct communication with the source.

Customer Testimonials

"Switching to manufacturer direct purchasing has saved us 20% on our packaging costs. The quality is exceptional, and the process is seamless." - Jane Doe, CEO of ABC Ltd.

"We have successfully reduced our environmental footprint by opting for eco-friendly packaging. Our customers appreciate the effort, and it's been great for our brand image." - John Smith, Marketing Director of XYZ Corp.

Interactive Cost Calculator

Use our interactive cost calculator to estimate your savings for bulk and custom orders.