In today’s fast-paced market, packaging is more than just a container — it's an essential element of brand identity, customer experience, and operational efficiency. Among the many options available, custom plastic packaging bags have emerged as a top choice for businesses across industries like food, retail, and e-commerce. Whether you're launching a new product line or optimizing your supply chain, understanding how to leverage bulk orders, competitive pricing, and direct manufacturer support can give your business a significant edge.

From Aesthetics to Durability: Why Plastic Packaging Bags Stand Out

Plastic packaging bags offer a unique combination of visual appeal and functional performance. They are lightweight yet strong, moisture-resistant, and capable of preserving product integrity from warehouse to doorstep. More importantly, they provide a blank canvas for branding — allowing companies to imprint logos, taglines, and creative designs that resonate with their target audience.

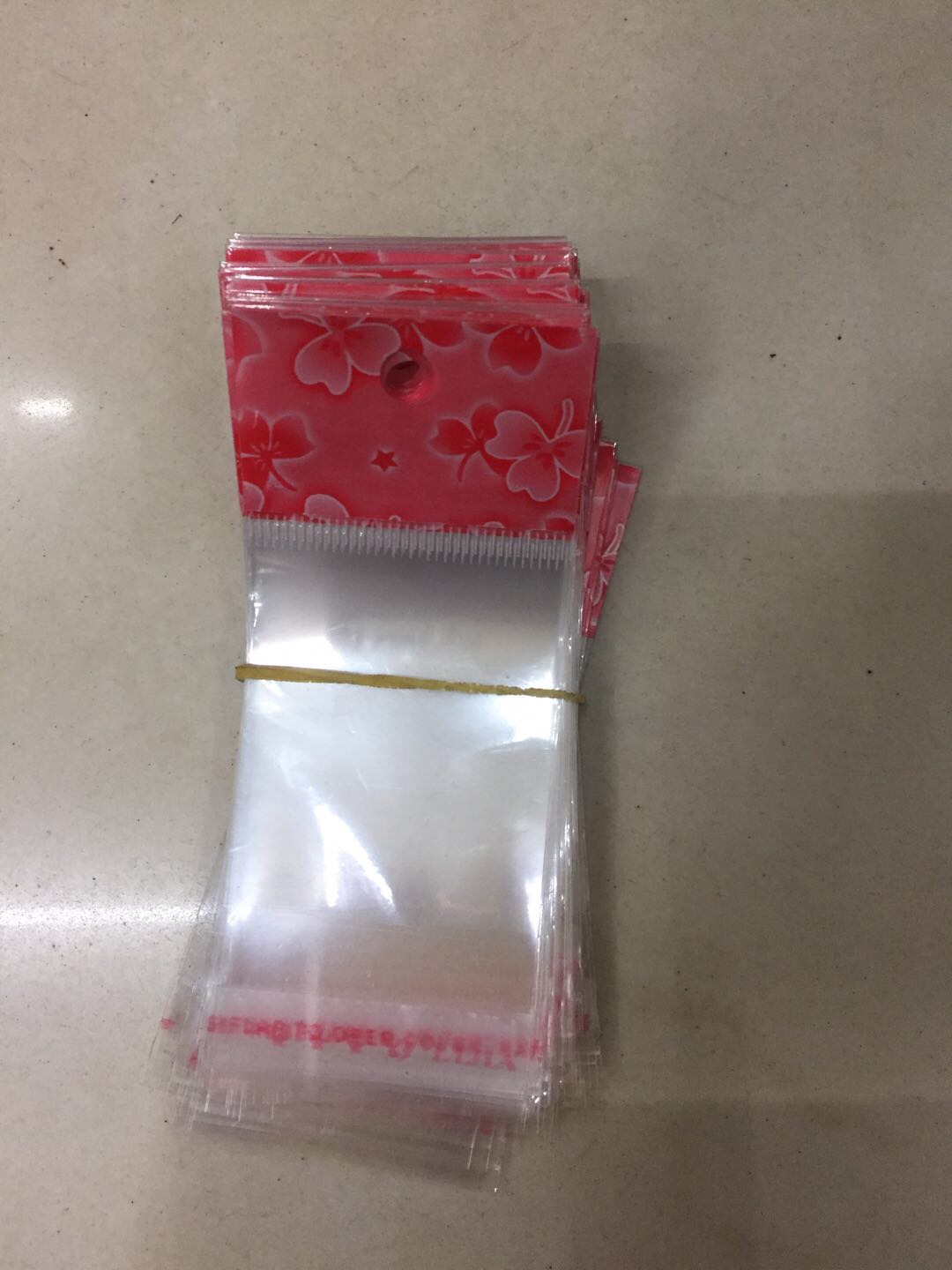

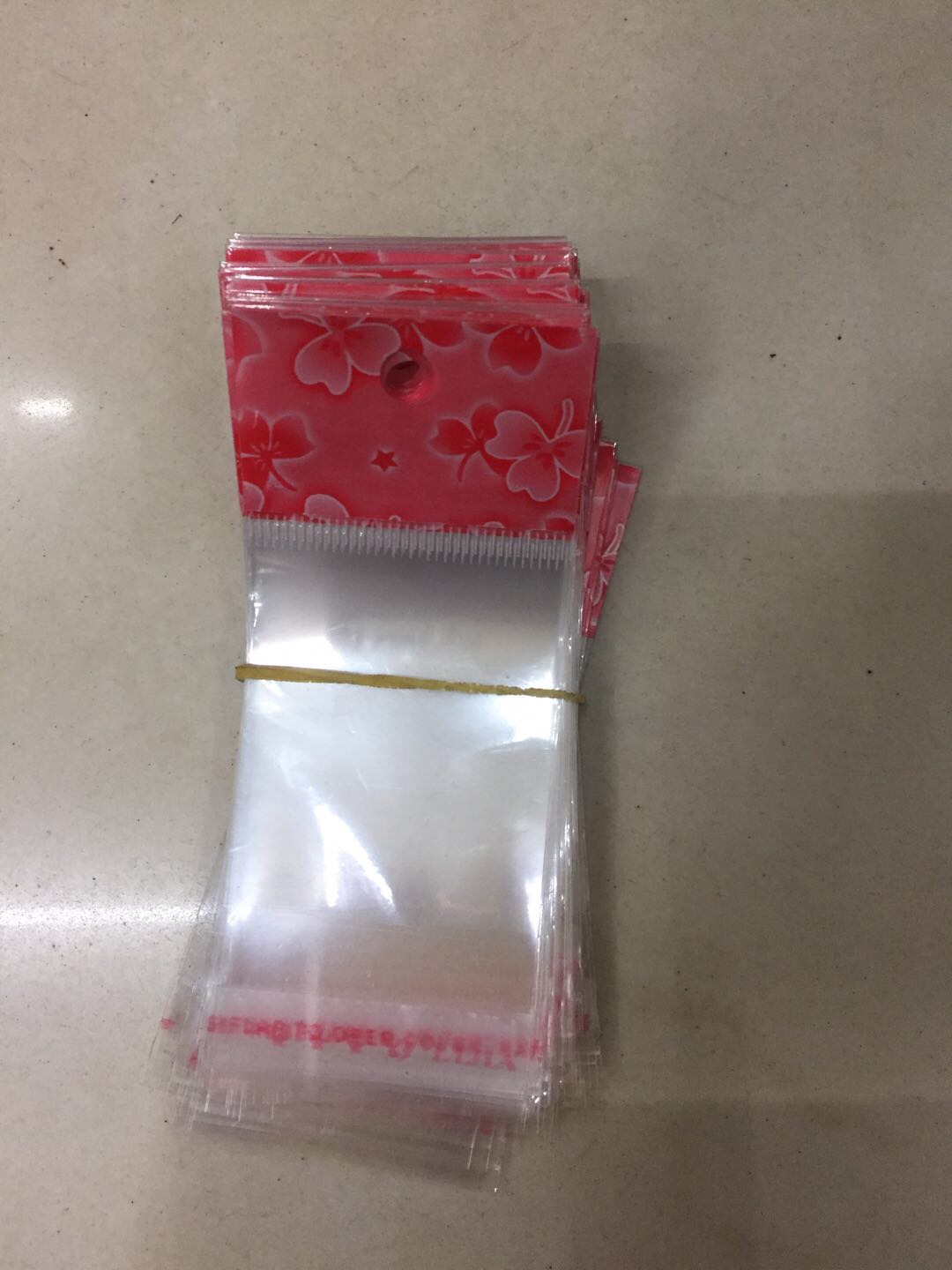

The flexibility of plastic packaging makes it ideal for various applications. For instance, food-grade materials ensure safety in perishable goods, while ziplock closures and resealable features enhance convenience for consumers. As consumer preferences evolve, so does the demand for personalized packaging — making customization a key differentiator in modern markets.

Economies of Scale: The Power of Buying in Bulk

One of the most compelling advantages of choosing plastic packaging bags in large quantities is cost efficiency. When businesses opt for bulk orders, they benefit from the principle of economies of scale — where the per-unit production cost decreases as volume increases. This translates into substantial savings without compromising on quality.

For example, ordering 10,000 units instead of 1,000 can reduce the unit price by up to 50%, depending on the specifications and manufacturer capabilities. Additionally, fewer orders mean lower shipping costs and reduced administrative overhead, streamlining logistics and improving cash flow. Many companies now adopt centralized purchasing strategies to consolidate orders and maximize discounts over time.

Branding Beyond the Logo: Designing a Unique Identity

Customization goes far beyond simple logo printing. Modern manufacturers offer a wide range of options including size variations, color palettes, material types (PP, PE, PVC), sealing mechanisms (zipper, heat-sealed, Velcro), and advanced printing techniques such as offset, flexographic, and digital. These choices allow brands to create packaging that aligns precisely with their product positioning and customer expectations.

A well-designed packaging solution not only protects the contents but also communicates professionalism and attention to detail. Brands like Apple and Coca-Cola have mastered the art of using packaging as part of their storytelling — turning even the unboxing process into a memorable brand moment. By investing in thoughtful design, businesses can significantly boost recognition and loyalty among repeat customers.

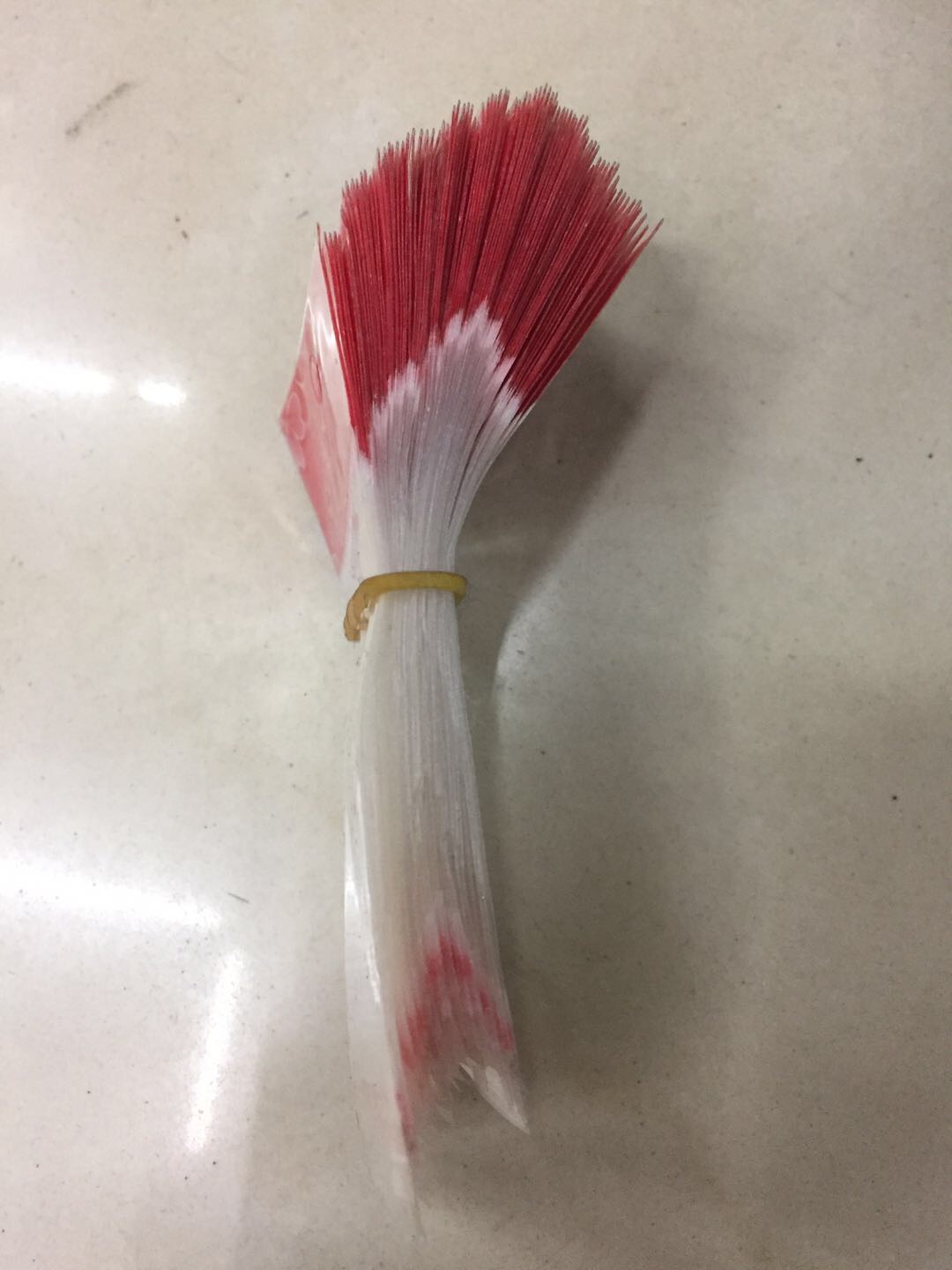

Why You Should Request Samples Directly From Manufacturers

Before committing to a large order, requesting free samples from direct manufacturers is a crucial step. It allows buyers to evaluate the actual quality, thickness, print clarity, and overall finish before mass production begins. Working directly with manufacturers often eliminates middlemen markups and ensures transparency in communication and production timelines.

When reviewing samples, pay close attention to factors like material strength, zipper functionality (if applicable), and ink durability under different conditions. It's also wise to assess the manufacturer’s responsiveness, willingness to accommodate revisions, and adherence to delivery schedules. A reliable supplier will be transparent about lead times and open to iterative feedback during the sampling phase.

Choosing the Right Supplier: What Matters Beyond Price

While competitive pricing is important, it should never come at the expense of reliability and service quality. The best suppliers go beyond offering low prices — they deliver consistent product standards, timely deliveries, and robust after-sales support. Here are some core qualities to look for:

- Rapid Communication: Quick response times indicate a professional and organized operation.

- Quality Assurance: ISO certifications or in-house QC processes are signs of commitment to excellence.

- Production Capacity: Large-scale facilities ensure stable supply even during peak seasons.

- Customer Support: Post-order assistance and problem resolution are critical for long-term partnerships.

- Sustainability Practices: With increasing regulatory pressure, eco-conscious suppliers are becoming a necessity rather than a luxury.

Looking Ahead: Sustainability and Innovation in Packaging

As global awareness around environmental issues grows, the packaging industry is undergoing a transformation. Biodegradable plastics, plant-based polymers, and recyclable materials are gaining traction among forward-thinking brands. In parallel, smart packaging technologies — such as QR codes for traceability, temperature indicators for perishables, and anti-counterfeit features — are opening new avenues for engagement and security.

Businesses that proactively integrate these innovations into their packaging strategy will not only future-proof their operations but also appeal to a growing segment of environmentally conscious consumers. The shift toward greener practices is no longer optional — it’s a strategic imperative for staying relevant in the evolving marketplace.

Final Thoughts

Investing in custom plastic packaging bags isn't just about securing cost-effective solutions — it's about crafting a brand experience that stands out. Whether through eye-catching design, efficient bulk procurement, or working directly with reputable manufacturers, the right packaging strategy can elevate your brand and drive measurable growth. As sustainability and technology continue to shape the industry, staying informed and agile will be key to long-term success.