Imagine the moment a customer opens their package—the crinkle of the bag, the pop of the seal, the instant they see your logo perfectly printed in crisp color. That first touchpoint isn’t just functional; it’s emotional. In today’s crowded marketplace, your packaging is the first voice your brand uses to speak—and with custom plastic packaging bags, that voice can be bold, beautiful, and unmistakably yours.

From the shade of green that echoes your eco-values to the transparency that showcases your product, every detail sends a message. A matte finish whispers sophistication. A resealable zipper says convenience. And a perfectly proportioned shape ensures shelf dominance. These aren't just containers—they're silent ambassadors working 24/7 to build recognition, trust, and loyalty.

Why Buying in Bulk Is Smarter Than Ever for Growing Brands

Gone are the days when only big corporations could afford high-quality custom packaging. Thanks to direct-from-manufacturer access, small and mid-sized businesses now enjoy dramatic cost savings by cutting out middlemen. When you order through distributors or third-party platforms, markups can inflate prices by 30–50%. But when you source straight from the production floor, those margins vanish—replaced by real value.

Consider this: producing 5,000 units might cost $0.25 per bag, but scaling up to 50,000 drops the unit price to just $0.12—a 52% reduction. This isn’t about hoarding inventory; it’s about strategic foresight. With consistent branding across campaigns and seasons, bulk ordering locks in pricing, avoids future supply shocks, and keeps your operations running smoothly without last-minute scrambles.

The Real Power Behind Free Samples

Free samples aren’t just a marketing gimmick—they’re a critical step in perfecting your final product. One skincare startup tested three iterations of their stand-up pouch: adjusting gloss level, tweaking zip lock placement, and refining font clarity. After each round, they conducted blind consumer tests. The result? A 40% increase in perceived product quality and a surge in social media shares featuring their sleek new look.

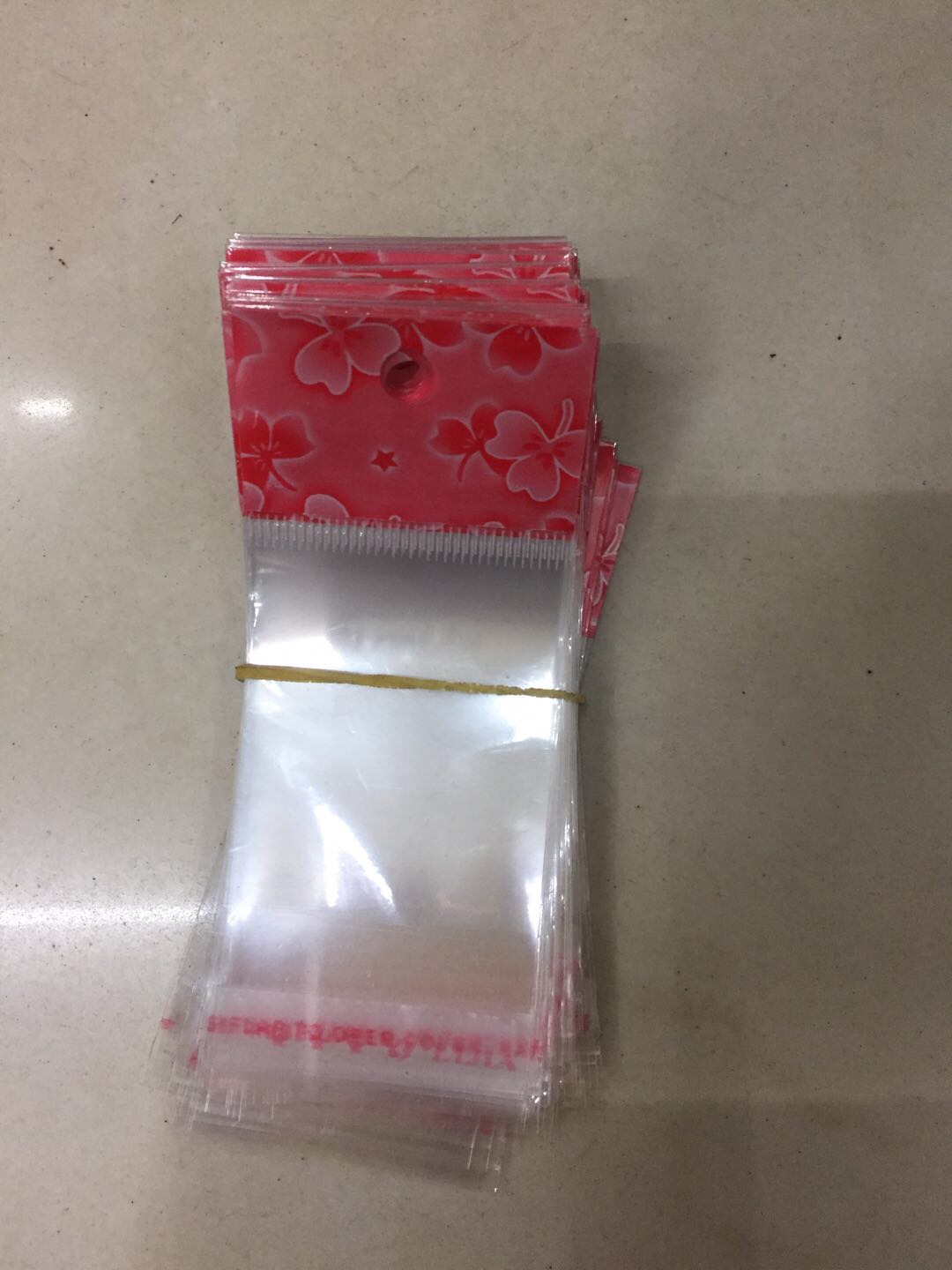

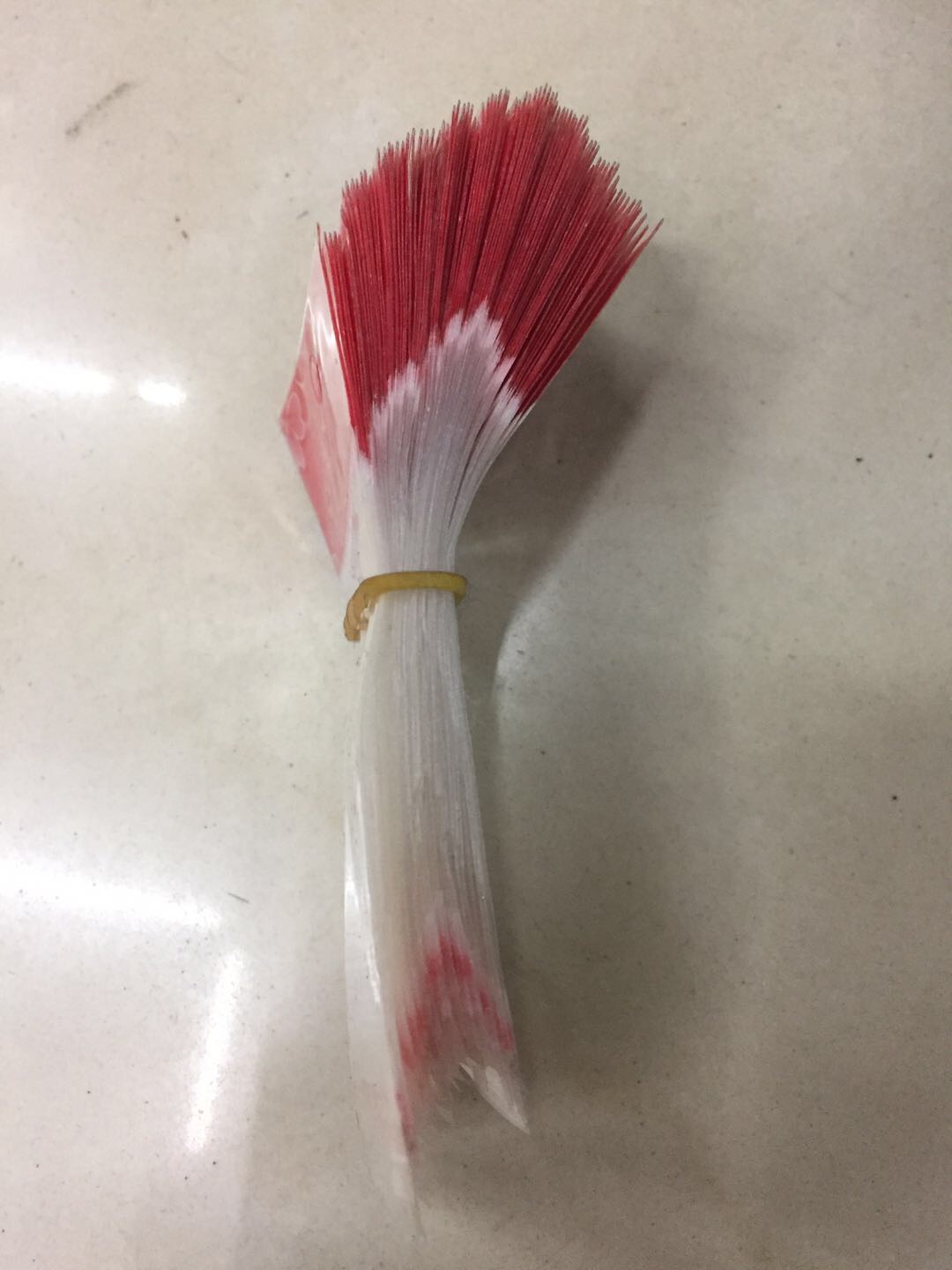

When evaluating samples, go beyond appearance. Test how the material feels between fingers, whether the seal holds under pressure, and if the print remains sharp after folding. Even minor flaws become magnified at scale. That’s why we encourage hands-on testing—because excellence lives in the details.

Make Your Bag Speak Volumes—Literally

Your packaging should tell a story. Whether it’s a hand-drawn illustration of mountain springs on a tea brand’s pouch or minimalist typography that screams modern luxury, printing techniques like silk screen, digital full-color, and metallic foil stamping transform ordinary bags into visual narratives. One coffee roaster used a panoramic scene of their farm across multiple panels—customers started sharing “unboxing videos” simply to show off the artistry.

Innovation isn’t limited to graphics. Resealable zippers preserve freshness. Gusseted bottoms allow bags to stand upright. Hang holes make retail display effortless. Each structural choice enhances usability and reinforces brand care.

Speed Meets Scale: Delivery in Just 7 Days

In the era of flash sales and seasonal launches, waiting weeks for packaging is no longer viable. Our streamlined manufacturing process—powered by localized facilities and smart scheduling—delivers custom orders in as little as seven days. For e-commerce brands syncing packaging with pre-order timelines, this speed means confidence in launch readiness.

Durability Tested Where It Matters—In Real Life

We don’t just claim strength—we prove it. Our industrial-grade LDPE, HDPE, and multi-layer co-extruded films undergo rigorous trials, including machine washing, drop tests, and puncture resistance checks. Compared to flimsy retail bags, our custom solutions reduce transit damage by up to 70%. And with reusable designs gaining favor, durability also supports sustainability—fewer replacements mean less waste.

Tailored Solutions for Every Industry

Food brands rely on oxygen-barrier layers and FDA-compliant materials to keep goods fresh. Beauty lines demand crystal-clear visibility and smudge-proof printing for premium appeal. Electronics need anti-static protection and cushioned interiors. Cross-border sellers benefit from lightweight, weather-resistant films built for global shipping. No matter your niche, there's a bag engineered specifically for your needs.

How to Spot a True Manufacturer (Not Just a Middleman)

Look for partners who offer mold development support, hold ISO and food safety certifications, and respond with technical precision—not generic replies. A reliable factory treats you as a long-term collaborator, advising on material choices and lead times rather than pushing quick sales.

The Future of Packaging: Designed to Be Photographed

Today’s consumers don’t just use packaging—they interact with it. Expect rising trends like minimalist layouts, hidden QR codes revealing origin stories, and tactile finishes that invite touch. The ultimate goal? Creating a bag so distinctive, people want to post it online. Because when your packaging becomes shareable content, your brand grows organically.

Start Your Custom Packaging Journey in Three Simple Steps

Begin by defining your purpose: what message should your bag convey? Then request free samples and test them with your actual product—shake, ship, store, and assess. Finally, choose a quantity tier that balances upfront savings with growth flexibility. With manufacturer-direct pricing and no hidden fees, your brand gets premium packaging without the premium price tag.

Ready to turn your packaging into a powerful brand asset? Request your free sample today—and see how a simple bag can say everything.