In today’s competitive market, packaging is more than just a container for your product — it’s a powerful branding tool, a promise of quality, and a key player in customer satisfaction. Whether you're in the food, cosmetics, or electronics industry, choosing the right packaging solution can significantly impact your brand's success. That’s where custom plastic packaging bags come into play.

Custom plastic packaging allows businesses to tailor every detail — from size and material to design and functionality — to match their unique product needs and brand identity. Whether you're looking to protect delicate items, enhance shelf appeal, or offer a resealable solution, the flexibility of customization ensures your packaging supports your business goals.

Why Go Big? The Power of Bulk Custom Packaging

One of the most effective ways to maximize value is through bulk production. Ordering large quantities of custom plastic packaging bags not only reduces the cost per unit but also ensures consistency across your product line. This is especially crucial for brands looking to maintain strong supply chain performance and meet customer demand efficiently.

A well-known example is a skincare brand that switched to bulk custom packaging and managed to reduce per-unit costs by 30%. This allowed them to reinvest in marketing and improve their pricing strategy, making their products more competitive in a crowded market.

Manufacturer Direct: Cut Out the Middleman for Better Value

When you work directly with a manufacturer, you eliminate unnecessary markups and gain access to more personalized service. Many brands are now opting for this direct-to-source model to secure better pricing, faster turnaround times, and more transparent communication throughout the production process.

Manufacturers who offer direct partnerships can quickly adapt to design changes, accommodate special requests, and provide tailored support based on your specific needs. This level of responsiveness is often difficult to achieve when working through third-party suppliers.

Printing Options That Tell Your Brand’s Story

Custom printing is one of the most impactful features of plastic packaging. With advanced printing technologies like digital and screen printing, brands can bring their creative vision to life with vibrant colors, sharp text, and intricate graphics. Whether you’re aiming for a minimalist look or a bold visual identity, the right printing method can make all the difference.

The key is to align your printing choices with your target audience. For instance, food packaging may benefit from clear, appetizing imagery, while luxury cosmetics might lean toward sleek, high-gloss finishes. A professional print finish not only elevates your product’s appearance but also builds consumer trust in your brand.

Try Before You Commit: Why Samples Matter

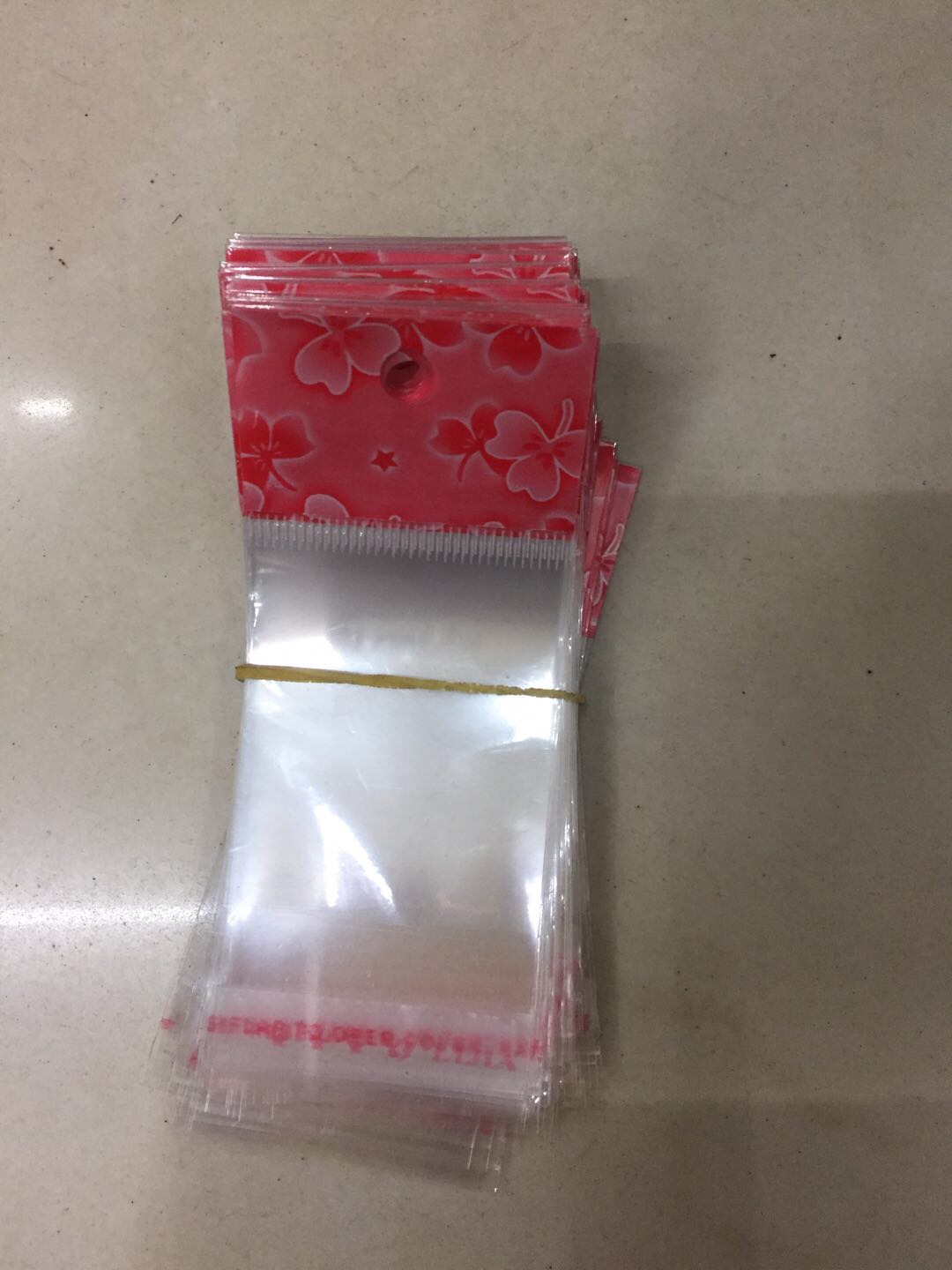

Before placing a large order, it’s wise to request samples. These allow you to test the material quality, printing accuracy, and overall functionality of the packaging before full-scale production. Many manufacturers offer free or low-cost samples to help brands make informed decisions.

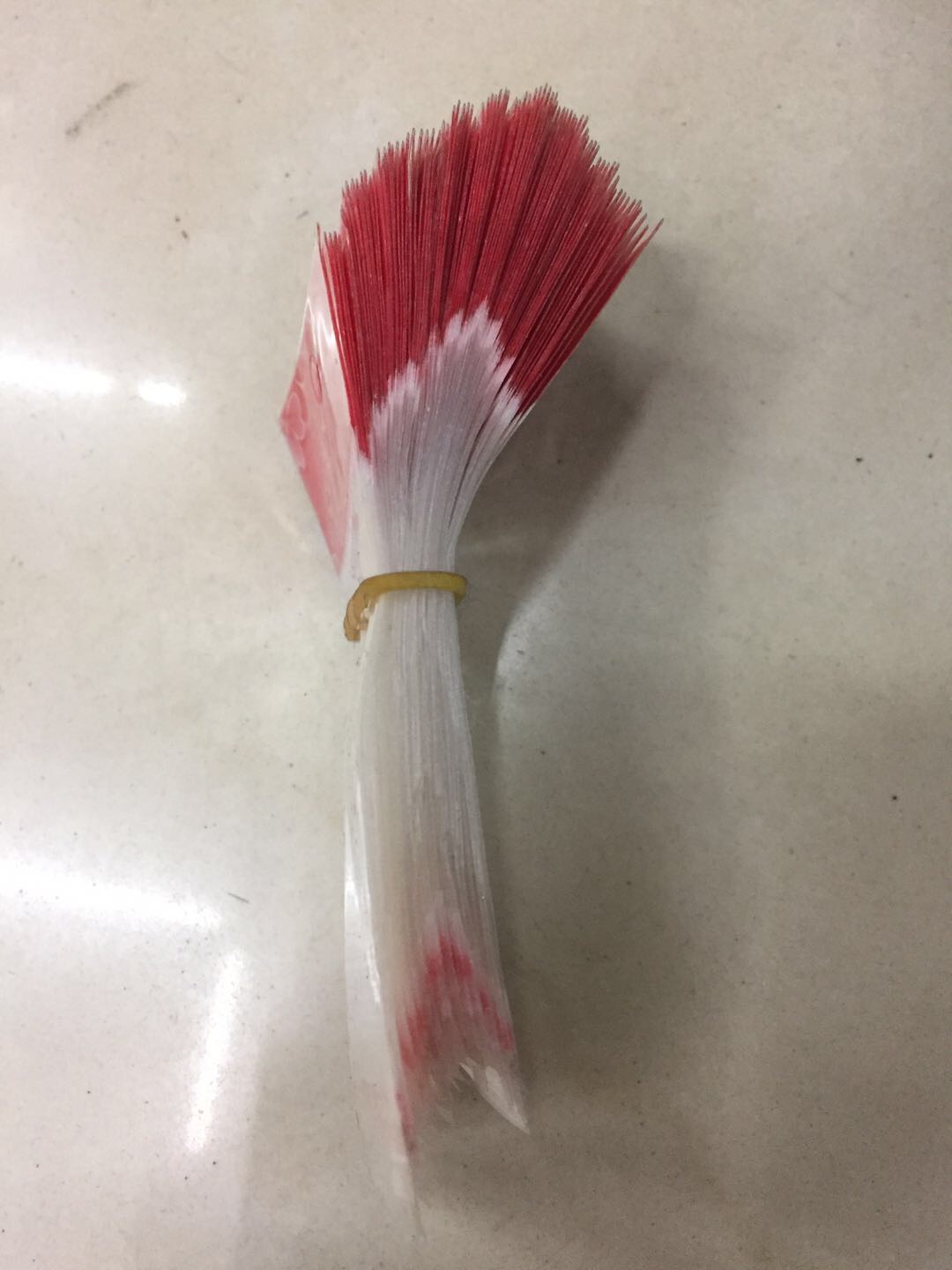

When evaluating samples, pay close attention to factors like thickness, durability, seal integrity, and how well the printed design translates from digital mockups to the final product. This step can save you from costly mistakes and ensure your packaging meets both aesthetic and practical expectations.

Choosing the Right Packaging Type: From Material to Functionality

Not all plastic packaging is created equal. Different materials such as PE (polyethylene), PP (polypropylene), and PVC (polyvinyl chloride) offer varying levels of flexibility, durability, and barrier protection. Understanding these differences helps you select the ideal packaging for your product’s needs.

Additionally, the type of bag you choose — whether it's a ziplock bag, stand-up pouch, or vacuum-sealed bag — plays a critical role in usability and presentation. For example, stand-up pouches are ideal for retail display, while vacuum-sealed bags are perfect for preserving freshness in food products.

Sustainability Meets Innovation: The Future of Eco-Friendly Packaging

As consumer awareness around environmental impact grows, so does the demand for sustainable packaging solutions. Fortunately, advancements in biodegradable and recyclable plastics now allow brands to reduce their ecological footprint without compromising on quality or aesthetics.

By choosing eco-conscious materials and optimizing package design to minimize waste, businesses can align with global sustainability trends while still delivering functional, attractive packaging. Some manufacturers even offer hybrid solutions that combine biodegradable materials with traditional plastic elements to balance cost and environmental responsibility.

The Next Frontier: Smart Packaging and Industry Innovation

The future of plastic packaging is being shaped by technology. From smart packaging embedded with QR codes for product tracking to temperature-sensitive labels that ensure product safety, innovation is opening up new possibilities for brand engagement and supply chain efficiency.

Manufacturers are increasingly adopting automation and AI-driven systems to streamline production, improve accuracy, and reduce waste. As these technologies become more accessible, even small and medium-sized businesses can benefit from cutting-edge packaging solutions that were once only available to large corporations.

Real Results: A Success Story in Custom Packaging

One brand that successfully leveraged custom plastic packaging is a rising tea company looking to stand out in a saturated market. By working directly with a manufacturer, they designed a line of resealable, eco-friendly pouches with custom printing that highlighted their organic ingredients and brand values.

The result? Increased customer satisfaction, a stronger brand identity, and a 20% rise in repeat purchases. Their success highlights the importance of strategic packaging decisions and the value of a collaborative relationship with a responsive manufacturer.

Get Started Today: Launch Your Custom Packaging Project

Ready to elevate your product with custom plastic packaging? Start by identifying your packaging needs — including material, size, printing preferences, and quantity. Then reach out to a trusted manufacturer to discuss your vision and request samples.

Clear communication is key. Provide detailed specifications, ask about lead times, and confirm quality control processes before moving forward. With the right partner, you can enjoy cost-effective, high-quality packaging that supports your brand’s growth and long-term success.